Undiscovered ideas and challenging endeavors create extraordinary plastic.

SEKISUI SEIKEI’s extrusion technology caters to customers’ needs in a variety of fields.

We continue improving our extrusion molding technological capabilities to expand the areas of contribution from miscellaneous general-purpose products to cutting-edge devices.

What is extrusion molding?

Extrusion molding is a molding method in which raw material placed in a hopper (such as a mixer) is melted and mixed in an extruder screw, extruded into a sheet shape through a mold (T die) on the tip, and cooled and surface-formed by a forming roll.

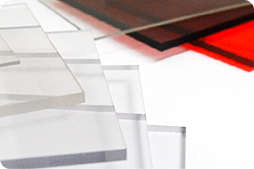

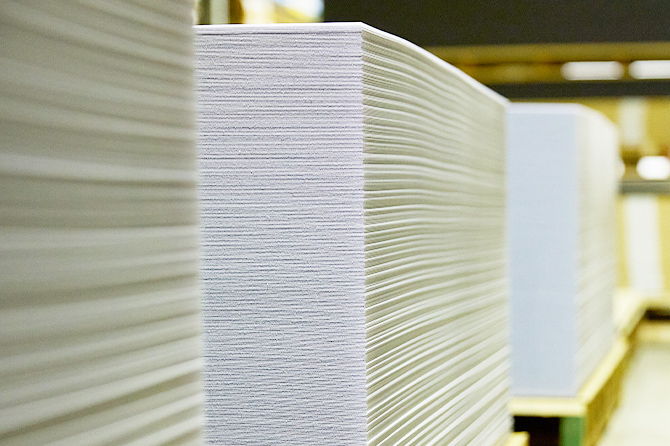

Hard plates

Polysame

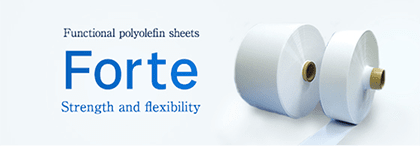

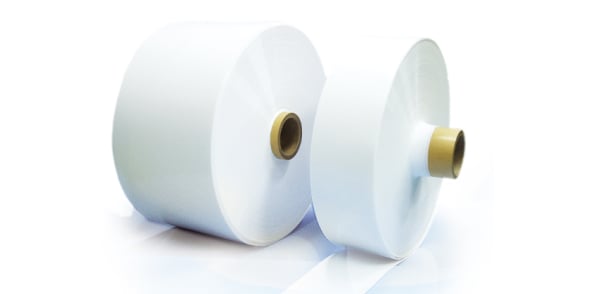

Functional roll sheets

Shape retaining sheet

(Forte)

Features of extrusion molding

Wide range of adaptability to meet required product thickness, width, and length. Suitable for producing sheets or rolled products that are needed in continuous processing.

Secondary processing for certain applications is also possible.

-

Various sizes

The strengths of extrusion molding can be used to achieve various production sizes from thick to thin, short to long, and sheet to roll.

-

Multilayer molding

The addition of equipment enables multilayer extrusion molding that can create various features.

-

Secondary processing

Extrusion molded products are also suited to secondary processing for different applications, such as printing, cutting, slitting, surface lamination, and coating.

Extrusion molding process

-

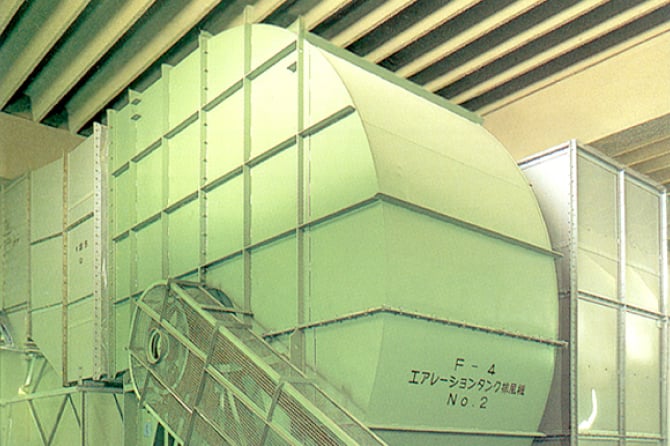

01Material preparation

Select the base plastic for the application and mix in additives as needed.

-

02T die extrusion

Extrude the heated molten plastic through the mold into sheets.

-

03Sheet forming

Cool the extruded plastic on a forming roll and process the surface as needed.

-

04Finishing

Wind rolled products and stack cut products.

SEKISUI SEIKEI’s technological capabilities

-

Film coating and design technology

We use our unique film coating technology to add functionality to products. The design can be flexibly adapted to assign various functions such as flame retardant or antistatic properties or to blend in recycled materials.

-

Size and thickness variations

We can make products in a wide range of thickness, from about 0.1 to 20mm. Product specifications for size can be matched to customers’ desired delivery size from sheets to rolls.

-

Total solutions

We offer a one-stop service with our processing functions. Through our partnerships with other manufacturers, we can provide total solutions covering all types of processing.

Bringing new value to a broad range of sectors.

SEKISUI SEIKEI provides plastic products matched to diverse needs.

We always pursue optimal plans and cost performance and use our industry-leading research development capabilities to deliver maximum value and satisfaction to customers.

-

IT

Electronics materials

Rechargeable battery materials -

Railway and automotive

Various interior materials

-

Daily living

Stationery and display

Packaging -

Medical care and pharmaceutical

Medical device materials

Hospital and facility interior materials -

Industrial

Plant materials

Utility materials -

Construction and civil engineering

Construction and interior materials

Waterproofing materials, agriculture

Main products

-

Esbilon Sheet / Plate

(PVC)Sekisui’s specialty hard PVC sheets and plates. We offer a lineup of products with excellent secondary processing capabilities and surface skin, chemical resistant products, UN-certified products, and more. They are highly versatile and contribute to all types of industries.

-

Eslon Plate

(Industrial PVC plate)Adaptable to diverse scenarios such as high impact, high heat resistance, and chemical resistance. We use the long length capabilities of extrusion molding to create products for a range of applications including plant construction, water treatment plants, and electrical equipment.

-

Estella

(PET plate)Estella plates offer the highest level of transparency among transparent plastic products. They are used in all types of fields for their flexible molding processability and printability and provide value to those fields.

-

TAFBILON

(Acrylic modified high impact PVC)We use the flame retardant and low smoke properties to offer a lineup of different grade products suited to applications in various fields such as automotive, aviation, medical devices, and housings.

-

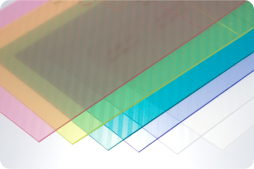

POLYSAME

(Stationery and packaging material)Can be flexibly adapted to create anything from highly transparent products to users’ original colors using our unique technology. Versatile PP sheets that offer superior surface texture, printability, and processability.

-

POLYELEC CARRIER TAPE

Lead frame spacerHigh performance sheets that combines our unique technology with high level specs to create a range of products such as carrier tape for transporting electronic parts, circuit board loading sheets, and various types of battery materials.

Related products page

-

List of sheet and plate products

Adaptable to all sorts of applications such as stationery, aviation, automotive, and medical care and pharmaceutical with a range of functions from thin sheets to thick plates.

-

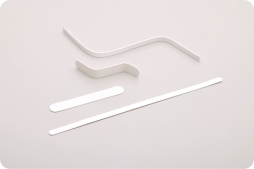

Forte

Forte is a plastic sheet material created with SEKISUI SEIKEISekisui’s unique orientation technology that retains its shape after bending, similar to metal or wire.