SEKISUI SEIKEI creates the highest level of safety for life- saving products.

Demand for semiconductor chemical, pharmaceutical, food product, and other containers is growing, and SEKISUI SEIKEISekisui’s blow-molded products provide excellent safety and cleanliness.

We have developed containers with different shapes, volumes, and functions to meet diverse needs and deliver superior safety.

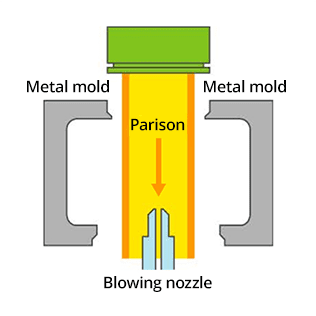

What is blow molding?

Blow molding is a type of plastic molding that is sometimes also called hollow molding.

Air is blown into heated molten plastic inside a mold to inflate it, forming products such as bottles with a hollow structure.

Being a single piece, it has excellent strength properties.

Rontainer

Polyethylene Container / Polydrum

Features of blow molding

Blow molding is the best molding method for creating hollow products like bottles. In addition to containers for everyday consumer goods, blow molding technology is also used for applications like large commercial containers, gas tanks, and portable toilets.

-

Hollow structure

Enables efficient molding of products with a hollow structure like bottles and tanks.

-

Economic performance

It is also economical, being better suited to medium-sized lots than other molding methods.

It may be the best option due to its excellent balance between initial investment and product cost. -

Multilayer molding

Multilayer molding, which is possible with specialized equipment, enables the creation of various functional features. One example is incorporating recycled materials into the middle layer to reduce both environmental impact and production costs.

Blow molding process

Molten resinHeated plastic is cylindrically extruded into the mold and air is blown inside to inflate it and form the shape.

-

01Parison injection

Molten resin is cylindrically extruded with an extruder.

-

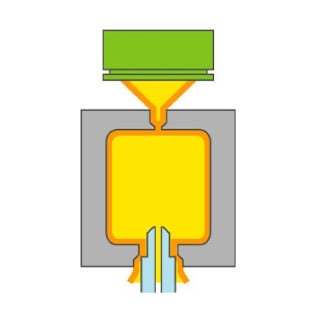

02Mold closing

The mold is slowly closed, with the parison clipped by the mold parts.

-

03Blowing to cooling

The parison is inflated with blown air within the mold and left to stand for a while for cooling down

-

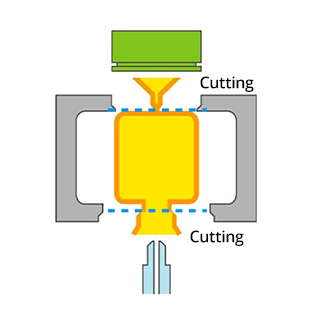

04Taking out the product

The product is taken out from the mold. Unnecessary parts (burrs) are removed and recycled.

SEKISUI SEIKEI’s technological capabilitie

-

UN certified containers

SEKISUI SEIKEI provides containers suitable for transporting hazardous materials that comply with global UN standards for transport. We offer many sizes of strong, chemical resistant containers with a high quality of dimensional accuracy that are essential for safe transport of the contained liquid.

-

Clean containers

Clean container is a highly purified container designed to minimize contamination by fine particles and suppress metal elution into the contained liquid. It contributes to the transportation and storage of high-purity chemical solutions, particularly in the semiconductor industry, through a clean manufacturing environment, careful selection of raw materials, and strict quality control.

-

Sterile

Single-use bagsSEKISUI SEIKEI offers single-use sterile bags for biopharmaceuticals. These feature a high level of sterility, low elution, and high transportation strength through advanced production and quality control processes. They can also be adapted to various assembly systems to suit customers’ processes.

Main sectors where the product is used

-

Electronics(semiconductors, displays)

-

Life sciences(biopharmaceuticals, test reagents, alcohol-based preparations)

-

Industrial(automotive industry, surfactants, inks)

-

Food sector(food product ingredients and flavorings, additives, alcoholic beverages)

Main products

-

Clean container

These high-purity containers are manufactured under strict control of particle contamination and elution impact into the contents, specifically designed for use with electronic materials. A wide range of sizes is available, from laboratory to mass-production scale.

-

Polyethylene Container

Poly containers primarily in the 20L class. Caters to the desired specifications such as UN certified and clean-compliant.

-

Rontainer

Bag-in-box (BIB) type container widely used in food and general chemical applications. Being collapsible, they can save inventory and disposal space

-

Steritainer

These single-use bags are designed for the safe transport and storage of biopharmaceutical products.

-

Polydrum

200L drum containers made entirely of plastic. Products for various uses are available, including UN certified, clean-compliant, and low residue type.

-

Volume reduction bottles

Eco-friendly containers that are light and can be crushed after use to reduce space.

Related products page

-

List of container products

Information on SEKISUI SEIKEI products with various functions such as superior cleanliness and compatibility with sterile environments.

-

Clean containers

Information on clean container used to safely transport and store liquids that require strict quality control.

-

Steritainer Plus

Examples of Steritainers used in a variety of fields.