Sheets and plates

Ultra-high molecular weight polyethylene plate ESLON® POLYBOARD-UM

Ultra-high molecular weight polyethylene with a molecular weight approximately 10 times or more higher than that of ordinary polyethylene

Molded at low pressure using ultra-high molecular weight polyethylene with a molecular weight of 3.5 to 5 million as a raw material (light-scattering method). Has among the top abrasion resistance, sliding properties, and impact resistance properties among many plastics. The operating temperature range is from an ultra-low temperature of -100°C or less up to 90 to 100°C. With a specific gravity of 0.94, it is also one of the lightest plastics.

Features

Abrasion resistance

Has the highest degree of abrasion resistance among plastic materials and far surpasses that of steel.

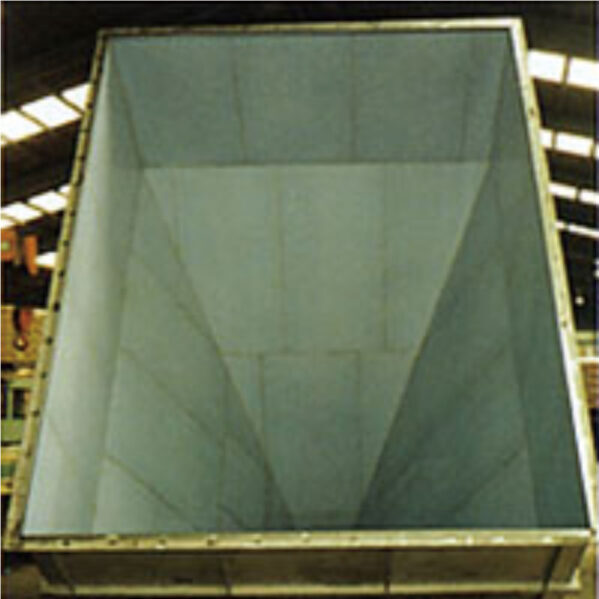

Sliding properties and self-lubricity

Has advanced properties compatible with those of fluororesin, so it is used for many applications such as gears, bearings, and hopper lining materials.

Chemical resistance

Except for some highly concentrated strong acids and organic solvents, it is resistant to most chemicals.

Electrical properties

Excellent electrical insulation and outstanding high frequency properties.

Cold resistance

Does not become brittle even at an ultra-low temperature of -100°C or less and demonstrates stable properties.

Others

Has many other features such as light weight (specific gravity 0.94), resistance to stress cracking, and excellent processability.

Products

UM-103W (White)

UM-103G (Green)

UM-103BK (Black)

UM-113BK (Black, antistatic)

UM-105Y (Yellow, high abrasion resistance)

Example applications

Hopper lining

List of product standards

Polyboard UM (ultra-high molecular weight polyethylene plate)

|

Item number

|

Type | Color | Size (mm) | Thickness (mm) | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 8 | 10 | 12 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | 80 | 90 | 100 | 120 | ||||

|

UM-103W

|

General | White | 1000×2000 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 |

| 1200×2400 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | ||||||||||||||

|

UM-103G

|

Green | 1000×2000 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |||||||||

| 1200×2400 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | ||||||||||||||||

| UM-103BK | Black | 1000×2000 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | |||||||||

| UM-113BK | Antistatic | Black | 1000×2000 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | ||||||||

| UM-105Y |

High abrasion resistance

|

Yellow | 1000×2000 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 | 〇 |